However, not many people are aware how these drugs are produced, distributed, prescribed or even how they actually work.

Most folks who are not trained as pharmacists or doctors (i.e. the majority of humans) just use these precious products without thinking twice about their origins . As long as these colourful pills work they are happy to keep using them.

As we see in the case of antibiotics, this casual and almost blind faith in popping pills has resulted in the slow erosion of the very effectiveness of these medicines.

So, at least now, let us figure out the answer to the question – how exactly are antibiotics produced?

Using microbes to fight microbes…

Surprising as it may sound, antibiotics have been produced in nature for millennia by microbes themselves, mostly for use against their fellow microbes!

Analysis of the lineage of several antibiotic resistance genes in bacteria has revealed that some of them have been around for nearly two billion years!

And much before the modern era of antibiotics, there is evidence that ancient civilizations too had discovered a variety of such naturally available antibiotics for treating various infections.

One such successful treatment was the topical application of mouldy bread, with many references to its beneficial effects from ancient Egypt, China, Serbia, Greece and Rome.

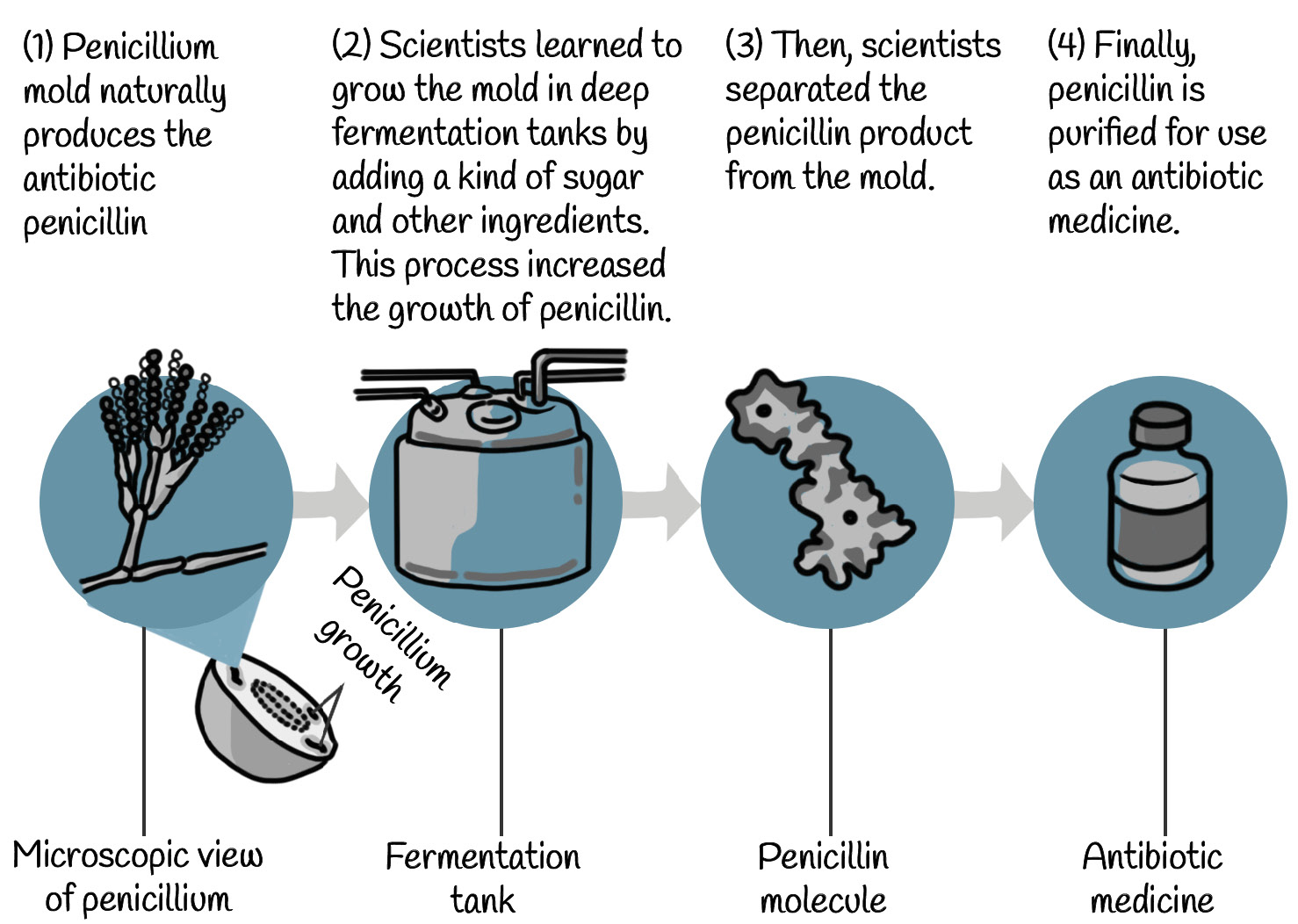

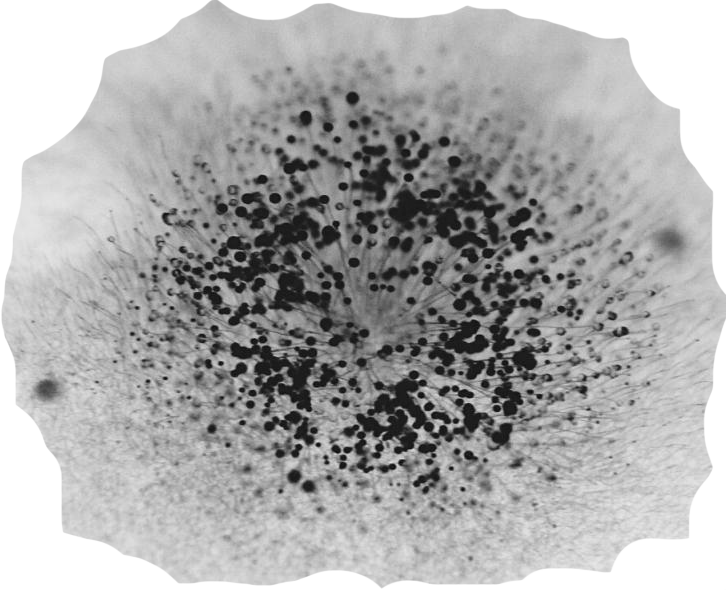

Much later, in 1928, this is exactly the phenomenon that Dr Alexander Fleming stumbled upon in his lab when he discovered that colonies of the common staphylococcus aureus bacteria were worn down or killed by the mold (fungus) growing on the same plate or petri dish. Fleming experimented further and determined that the mold made a substance that could dissolve the bacteria. He called this substance penicillin, named after the Penicillium notatum mold that made it.

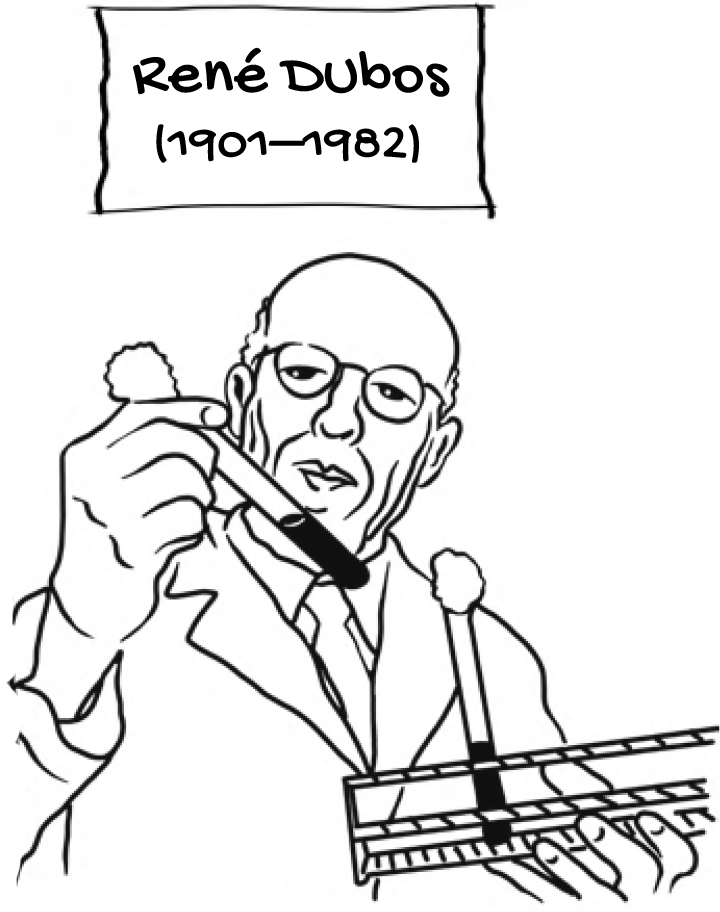

These were the first

antibiotics from soil bacilli to be produced commercially.

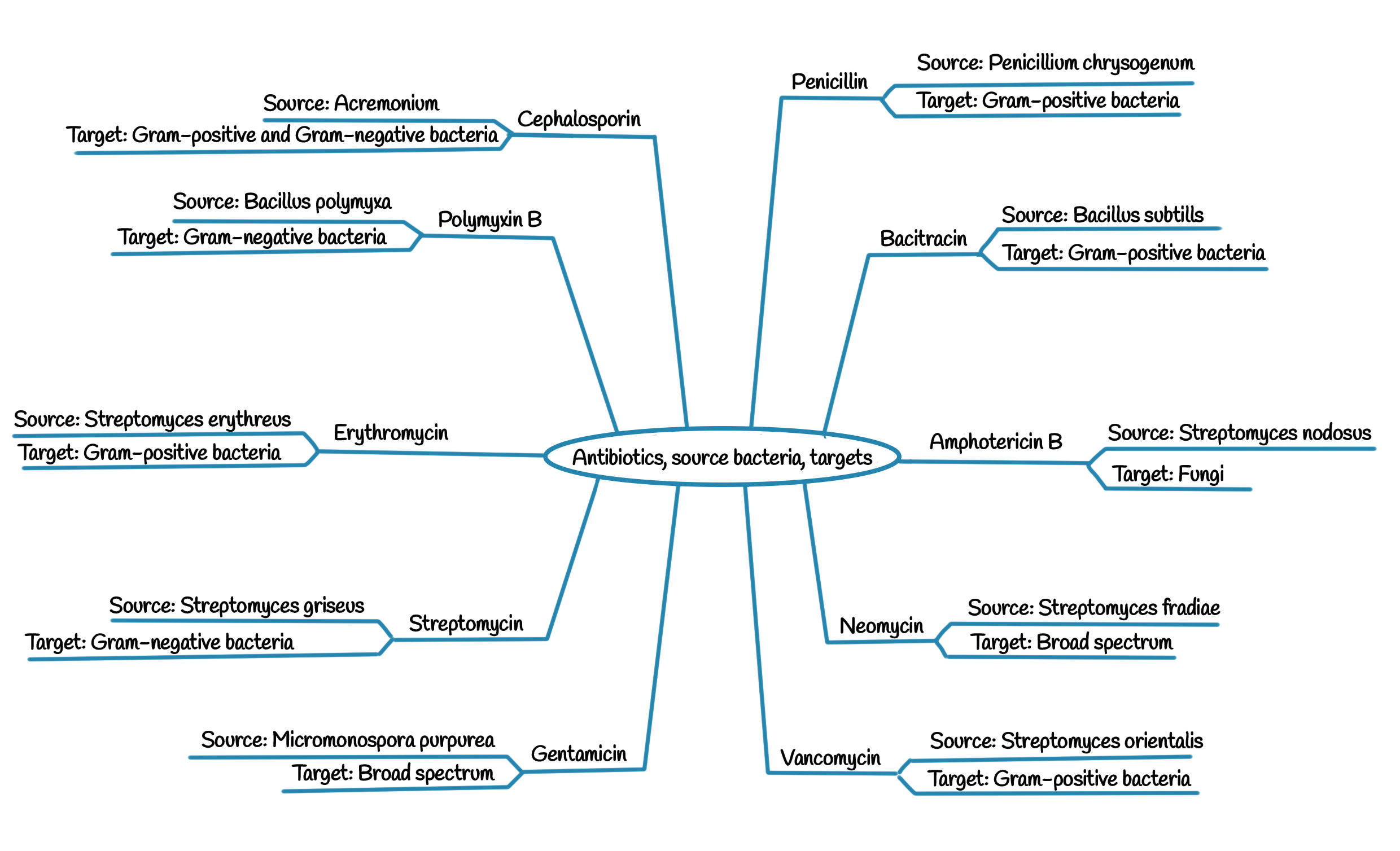

In 1944 Selman Waksman isolated the antibiotic streptomycin from Streptomyces griseus, an organism found in soil.5 He received the Nobel prize in 1952 for discovery of the first antibiotic effective against tuberculosis.

Similarly, in 1948 cephalosporins, one of the most important drugs for treatment of bacterial infectious diseases, were produced from Acremonium chrysogenum, a slow growing fungus.

A soil sample from Borneo in 1952 had the bacteria Streptomyces orientalis, from which vancomycin, another very important antibiotic, was eventually extracted and became available for patient use in 1958. Streptomyces are the largest antibiotic-producing family of bacteria, producing over two-thirds of the clinically useful antibiotics of natural origin.

The remarkable richness of microbial natural products as sources of antibiotics reflects the fact that they are products of evolution, selected over millennia for interaction with biological targets.

Antibiotics from artificial sources

Strictly speaking: antibiotics are organic anti-infective agents that are derived from bacteria or molds that decrease multiplication or kill other bacteria.

However, the term antibiotic is now used loosely to include anti-infectives produced from man-made synthetic and semi-synthetic compounds. In fact, the earliest two antimicrobials of clinical utility were synthetic molecules.

In synthetic or semi-synthetic antibacterials usually chemicals related to natural antibiotics are used to accomplish comparable tasks. Apart from sulphonamides other synthetic antibacterials include quinolones.

Production of antibiotics

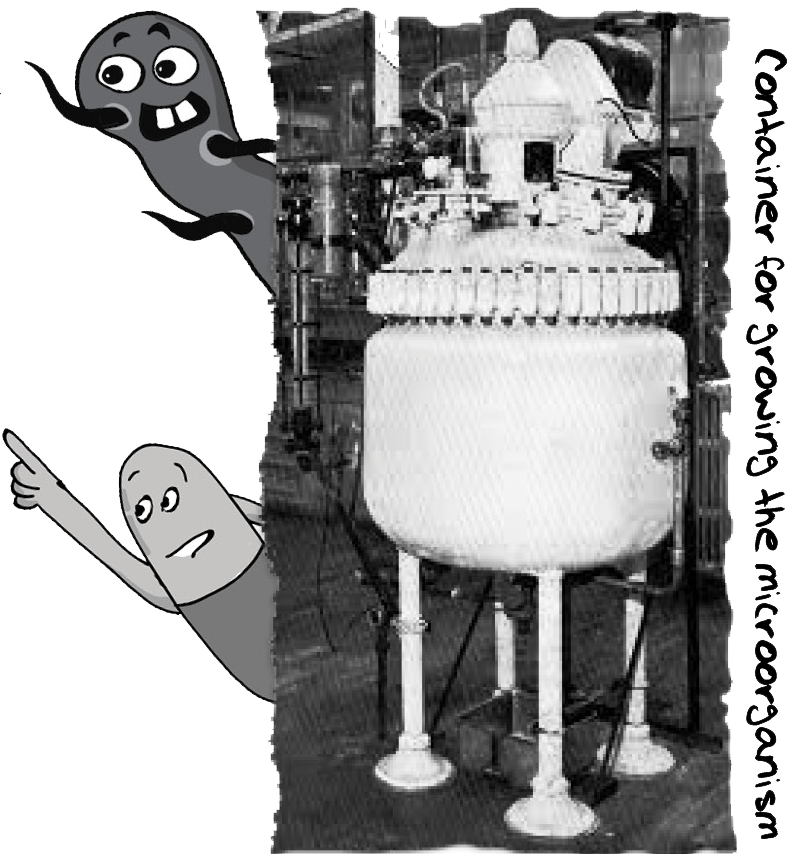

Typically, the production of antibiotics from natural sources is done through a fermentation process. The source microorganism is grown in large containers – with capacities of 100,000 to 150,000 litres – containing a liquid that facilitates their rapid growth.

The size of the bacterial population is controlled very carefully to ensure that maximum yield is obtained before the cells die. Then the antibiotic is extracted and purified into a crystalline product, for further processing before packaging into pills, capsules or vials for medical use.

Microorganisms used in fermentation are often not the same as their counterparts in the wild. They are genetically modified to yield the maximum amounts of antibiotics. The development of higher yielding strains over many generations can raise antibiotic yields by 20-fold or more.

How did they make penicillin?