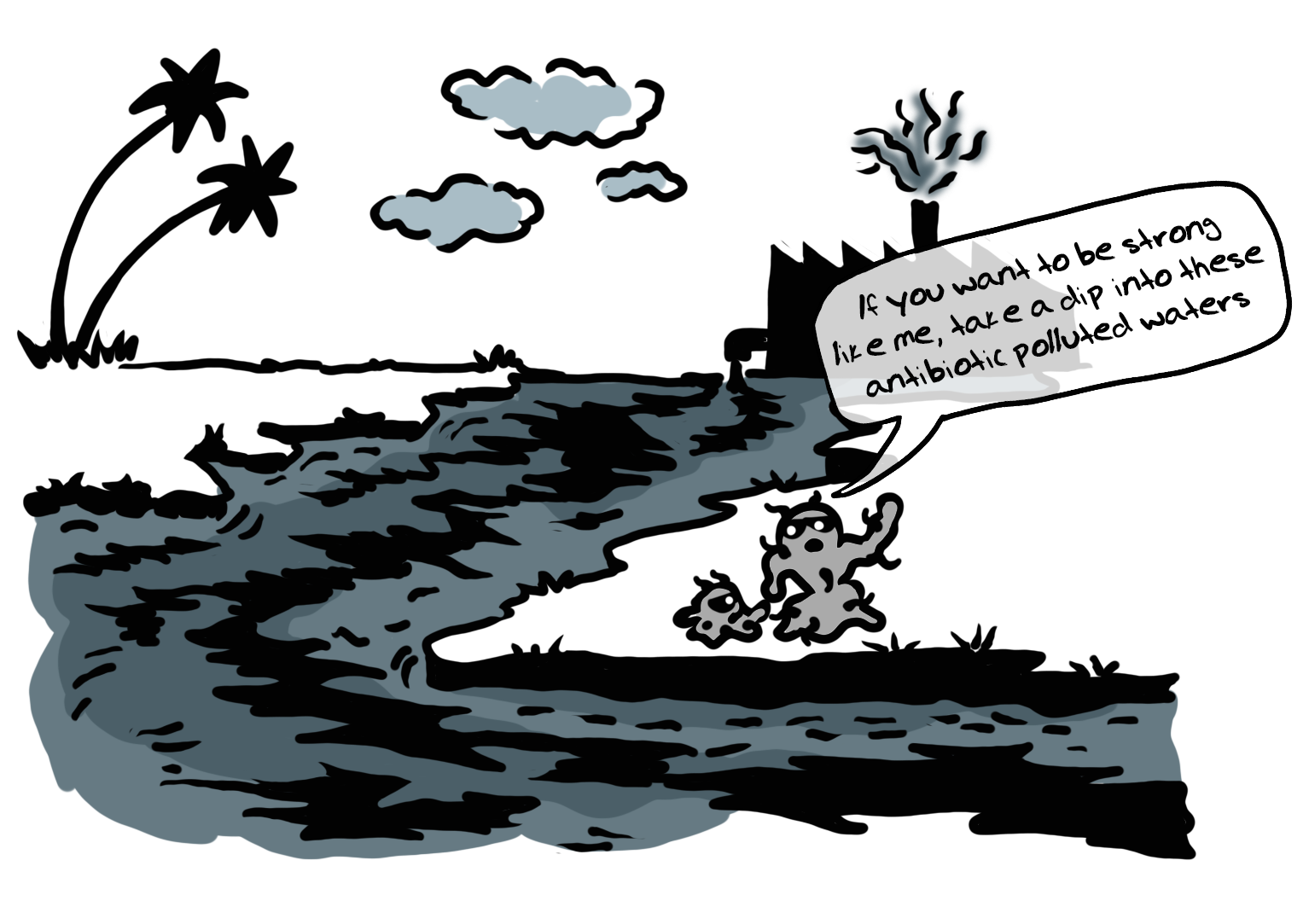

One of the great ironies in the story of how antibiotic resistance emerges and spreads around the world involves the role of drug manufacturers themselves.

Yes, believe it or not, the same companies that produce life-saving antibiotics contribute towards polluting the environment with antibiotic residues from their manufacturing plants.

One reason for this is of course, that the manufacturing of antibiotics on an industrial scale, particularly through the fermentation process, with discharge of waste into nearby water bodies, can be…

The concentration of antibiotics in effluents from antibiotic-manufacturing sites can reach extremely high levels.

Apart from the toxic effects of such antibiotic concentrations on living organisms, such unchecked discharge of antibiotics also leads to an increase in bacterial resistance genes in the environment.

The message here is simple:

Polluting the Earth is the same as poisoning our own bodies!

What is the solution?

In response to growing worldwide concerns about antimicrobial resistance, in 2018, the AMR Industry Alliance, a global coalition of private pharma manufacturers, developed The Antibiotic Manufacturing Framework to ensure adequate control of manufacturing effluent emissions.

It sets out minimum standards for companies to adhere to environmental compliance and appropriate antibiotic discharge management. The focus is on:

• Setting up minimum requirements for water management,

• Solid waste management programs as well as conducting audits of antibiotic manufacturers.

Among the measures suggested was calculating API discharge amounts, called the Predicted-No-Effect Concentration (PNEC) or antibiotic concentrations at which, the Alliance believes, the selection pressure is minimal on microbes in the environment to mutate and develop drug resistance.

One way to tackle pollution at antibiotic manufacturing plants while ensuring access to low cost medicines is to tackle the problem through a global process instead of leaving it to individual countries or companies alone.

Global standards are needed that guide and regulate the production of antibiotics to discourage environmentally damaging practices. Such regulation can be accomplished through restrictions on procurement from polluting factories coupled with subsidies and incentives for implementing

environmentally safe practices.

For example there could also be investments, in improving the supply chain or through preferential procurement of appropriate end products. For smaller manufacturers, which may have neither the financial capacity nor the technology to adjust to such requirements, an international system or Fund that would subsidize adjustments and provide access to technology should be considered. This is especially so, if such producers are committed to manufacturing good quality antibiotics needed in low and middle-income countries.